In the world of construction and engineering, there’s a force of nature that stands tall, strong, and often underappreciated—steel fabrication. It’s the backbone of modern architecture, the sturdy framework upon which we build our dreams. But what is steel fabrication, really? And why should you care about it? Buckle up, because we’re about to dive into the fascinating world of structural steel, where sparks fly, metal bends, and the results are nothing short of awe-inspiring.

Understanding Steel Fabrication

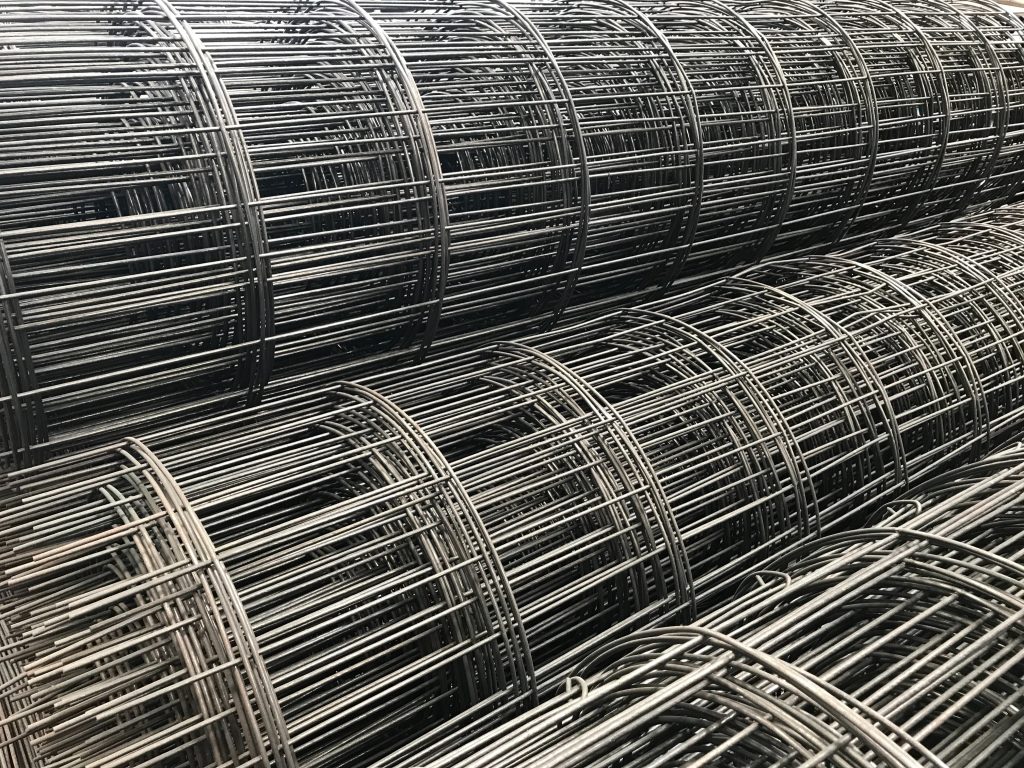

Imagine a blank canvas, except this canvas is made of steel sheets, beams, and rods. Steel fabrication is the creative process that transforms these raw materials into the structural components that support our skyscrapers, bridges, and industrial marvels. It’s not just about welding pieces together—it’s an intricate dance of design, engineering, and craftsmanship.

Key Components of Steel Fabrication

Before the sparks start flying and the hammers start pounding, we need to gather our materials and tools. Steel fabrication begins with selecting the right type of steel for the job. Will it be mild steel, stainless steel, or something exotic like weathering steel? The choice matters because it determines the strength, durability, and even the appearance of the final product.

Once we’ve got our steel, it’s time to cut and shape it. Modern fabrication workshops boast an arsenal of high-tech machinery—laser cutters, shearing machines, and powerful punches that can shape steel with precision and speed. It’s like watching a sculptor turn a block of marble into a masterpiece, only this sculptor wears a welding mask.

The Steel Fabrication Process

Now that we have our steel pieces ready, it’s time to put them together like a giant steel puzzle. This is where welding and bolting come into play. Skilled welders use various techniques, from MIG to TIG, to join pieces of steel with heat and precision. Bolting, on the other hand, involves using heavy-duty nuts and bolts to secure connections. Think of it as the industrial version of LEGO—it’s all about making sure every piece fits perfectly.

Quality control is the watchful eye that ensures everything meets the highest standards. Inspections, tests, and measurements are carried out to make sure that the final product is not only strong but safe.

Industries That Rely on Steel Fabrication

Now that you have a grasp of what steel fabrication entails, let’s talk about where it’s put to work. Structural steel is the unsung hero behind the scenes, supporting industries and infrastructure in ways you might never have imagined.

From towering skyscrapers that scrape the heavens to the intricate framework of our bridges, structural steel is the backbone of the construction industry. It’s like the scaffolding that holds up our urban jungles.

But the influence of steel fabrication goes beyond bricks and mortar. In the manufacturing world, it’s the secret sauce in the automotive, aerospace, and machinery sectors. From car frames to aircraft components, steel fabrication plays a crucial role in crafting the tools and machines that propel us into the future.

Even our infrastructure—railroads, airports, and utility structures—lean on steel fabrication to keep things running smoothly. It’s the infrastructure’s silent partner, working tirelessly to ensure our daily lives are safe and efficient.

Advantages of Steel Fabrication

Now that you’re acquainted with the world of steel fabrication, let’s talk about why it’s a preferred choice in construction and manufacturing.

Strength and Durability

Steel is like the superhero of materials—it’s incredibly strong and can withstand tremendous pressure and stress. Whether it’s holding up a skyscraper or supporting a massive aircraft, steel’s strength is unmatched.

Versatility in Design

Designers and architects love steel for its flexibility. It can be molded into nearly any shape or form, making it a designer’s dream. From the sweeping curves of modern architecture to the intricate framework of industrial machines, steel can be whatever you need it to be.

Cost-Effectiveness

Despite its incredible properties, steel is relatively cost-effective. Its durability means it requires minimal maintenance, and it has a long lifespan, making it a smart investment for construction projects.

Sustainability and Recyclability

In an age where sustainability is paramount, steel fabrication shines. Steel is highly recyclable, reducing waste and environmental impact. It can be melted down and repurposed infinitely without losing its strength or quality.

Challenges in Steel Fabrication

Of course, every superhero has its kryptonite, and steel fabrication is no exception. Here are some challenges that come with the territory.

Precision and Accuracy Requirements

When you’re dealing with structures that need to be precise down to the millimeter, there’s no room for error. Steel fabrication demands meticulous attention to detail and exacting standards. Check out Structural Steel Detailing, Precast Drafting and Rebar shop drawings pages.

Safety Concerns

Working with heavy machinery, intense heat, and massive steel structures is no walk in the park. Safety is a top priority, and the industry takes extensive measures to protect workers and the public.

Environmental Impact

While steel is recyclable, the production process does have environmental implications, including energy consumption and emissions. The industry is continually working on greener solutions to reduce its footprint.

Skill and Labor Demands

Skilled labor is essential in steel fabrication. Welders, fabricators, and detailers need specialized training and experience to ensure quality and safety.

Future Trends in Steel Fabrication

So, what does the future hold for steel fabrication? As technology advances and sustainability takes center stage, several exciting trends are emerging.

Automation and Robotics

Automation is streamlining the fabrication process, increasing efficiency, and reducing human error. Robots are now handling tasks like welding and assembly, leading to faster production times.

Advanced Materials

Researchers are constantly developing new steel alloys that are stronger, lighter, and more corrosion-resistant. These advanced materials open up new possibilities for design and construction.

Sustainable Practices

Environmental consciousness is driving the industry to adopt greener practices. From using recycled steel to reducing energy consumption, steel fabrication is becoming more sustainable.

Digitalization and BIM Integration

Digital tools like Building Information Modeling (BIM) are revolutionizing the way we design and fabricate steel structures. This technology allows for more accurate planning and coordination.

steel fabrication is the unsung hero behind the scenes of our modern world. It’s the art and science of transforming raw steel into the structures and machines that shape our lives. From strength and versatility to sustainability and innovation, steel fabrication continues to evolve, ensuring a strong and exciting future.

Now, the next time you walk past a skyscraper or drive over a bridge, you’ll have a newfound appreciation for the intricate dance of steel fabrication that made it all possible. For infomation visit Steel.org.au.

FAQ Section

What is the difference between steel fabrication and welding?

- Steel fabrication involves the entire process of creating structural components from raw steel, including cutting, shaping, and assembly. Welding is a specific step within fabrication where pieces are joined together using heat.

Is steel fabrication environmentally friendly?

- Yes, steel fabrication is considered environmentally friendly because steel is highly recyclable, reducing waste. Additionally, modern fabrication practices aim for sustainability by minimizing energy consumption and emissions.

How long does a typical steel fabrication project take?

- The duration of a steel fabrication project varies based on complexity and size. Small projects may take a few days, while larger ones, such as bridges or skyscrapers, can take several months to complete.

What qualifications do steel fabricators and detailers need?

- Steel fabricators and detailers often require formal education or apprenticeships in welding, drafting, or structural engineering. Certification in welding and familiarity with CAD software are beneficial.

What safety measures are important in steel fabrication?

- Safety is paramount in steel fabrication. Protective gear, proper ventilation, equipment maintenance, and adherence to safety protocols are essential to prevent accidents and health hazards.